Limited Time Offer: Enjoy 10% Off All Services

Get a quote now – this discount won’t last long!

We Show You How To Calculate Slopes & Gradients By Hand and Using Our Free To Use Calculators

Article By: Tom Ayre

Last Update: November 2020

Calculating a gradient slope is an important element of any building and civil engineering design project. Gradients are crucial to several elements of construction. Typical situations to in which you will need to calculate a gradient are:

In this blog article, I will be showing you how to calculate the gradient by hand, which will be useful for sites where you don’t have a calculator. We also have a calculator for each section, making the process even easier.

A gradient is a complicated word for quite a simple concept. The gradient refers to the change rate or how steep a slope is.

Take for instance a gradient of slope that is 1 in 100 (1:100)

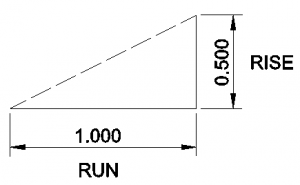

A 1:100 slope means that for every 100 metres along the ground, the slope height increases or decreases by 1 metre. A 1:0.5 slope means that for every 1 metre along the ground, the slope height increases by 0.5 metres.

A gradient can be expressed in 2 ways, a number or a ratio.

For instance, a 1:40 gradient number is shown as 0.025 (an example is shown in the calculation section).

The same number can be converted into a ratio

For instance, a ratio is shown as “1:40”

The following sketch should help.

Prior to calculating your gradients it is useful to know ground levels to calculate elements such as muck away volumes, pipe lengths etc. Consider employing a setting out engineer / company to undertake a precise topographical survey of the site to get this as accurate as possible!

So how do you calculate a gradient number? This is very simple. Just make sure you keep your run/rise units the same (meters, centimetres, miles, km etc)

Step 1: Work out the run length. This is the horizontal distance along the ground. Example number 60 metres.

Step 2: Work out the rise length. This is the vertical length going up. Example number 12 metres.

Step 3: Divide the rise length by the run length, in a calculator this would be 12 ÷ 60. This would equal a gradient of 0.2.

Example 1

Run length = 25 metres

Rise Length = 0.8 metres

Gradient = 0.8 / 25

Gradient = 0.032

Example 2

Run Length = 500 mm

Rise Length = 1200 mm

Gradient = 1200 / 500

Gradient = 2.4

Make sure you use the same units in both the run and the rise calculators. So keep things in metres, millimeters, centimetres etc.

So how do you calculate a gradient slope %? Again, this is very simple. Just make sure you keep your run/rise units the same (meters, centimetres, miles, km etc)

Step 1: Work out the run length. This is the horizontal distance along the ground. Example number 60 metres.

Step 2: Work out the rise length. This is the vertical length going up. Example number 12 metres.

Step 3: Divide the rise length by the run length, in a calculator this would be 12 ÷ 60. This would equal a gradient slope of 0.2 which is 20% (multiply by 100 if you need to).

Example Calculation 1

Run length = 25 metres

Rise Length = 0.8 metres

Gradient = 0.8/ 25 Gradient %= 0.032

Gradient % = 0.032 x 100

Gradient % =3.2

Example Calculation 2

Run length = 3200 mm

Rise Length = 750 mm

Gradient = 750/ 3200 Gradient % = 0.234%

Gradient % = 0.234 x 100

Gradient % = 23.438%

Make sure you use the same units in both the run and the rise calculators. So keep things in metres, millimeters, centimetres etc.

So how do you calculate a gradient ratio? Another bit of easy maths. Just make sure you keep your run/rise units the same (meters, centimetres, miles, km etc)

Step 1: Work out the run length. This is the horizontal distance along the ground. Example number 60 metres.

Step 2: Work out the rise length. This is the vertical length going up. Example number 12 metres.

Step 3: Divide the run length by the rise length, in a calculator this would be 60 ÷ 12 . This would equal a gradient of 5, this would then be shown as a ratio so = 1:5

Example Calculation 1

Run length = 25 metres

Rise Length = 0.8 metres

Gradient = 25/ 0.8

Gradient = 1:31.25

Example Calculation 2

Run Length = 500 mm

Rise Length = 1200 mm

Gradient = 500/ 1200

Gradient = 1:0.4166

Make sure you use the same units in both the run and the rise calculators. So keep things in metres, millimeters, centimetres etc.

If you know what your pipe needs to fall at (example 1:40, 1:20 etc) then you will need to know what the pipe needs to drop by over the length of the pipe.

Step 1: Work out the run length. This is the horizontal distance along the ground. Example number 60 metres.

Step 2: Work out required fall ratio (usually specified by designer). Example fall is 1:30

Step 3: Divide the horizontal distance by the fall number. Example would be 60 ÷ 30. Your fall in pipe therefore equals 2 metres.

Example Calculation 1

Run length = 25 metres

Fall ratio = 1:80

Pipe fall = 25 ÷ 80

Pipe fall = 0.3125 m

Example Calculation 1

Run length = 3250 mm

Fall ratio = 1:40

Pipe fall = 3250 ÷ 40

Pipe fall = 81.25 mm

Make sure you use the same units in both the run and the rise calculators. So keep things in metres, millimeters, centimetres etc.

Setting out a gradient for an important project should be undertaken by a reputable setting out survey company.

Prior to the setting out a topographical survey of the site should be undertaken to establish precise levels. This will help calculate muck away volumes, costs, pipes required etc.

Below we show a very simple method to setting out gradients without expensive equipment. Of course, this should only be utilised on small domestic projects where it is not so important you are spot on accurate!

Step 1 – Start by placing your timber pegs at the start and end of your drainage run. Using your mallet, bang the rods into the ground so they are nice and vertical and solid in the ground.

Step 2 – Using your string line, nail the string at the midway point on the first stake. Take the string line to the other stake and using your spirit level try to get the line as level as possible. You may need a second pair of hands. Level the line all the way along as best you can and ensure it is taught. This may take some time! Once you have done this use your permanent marker to mark the height of the string line at each peg.

Step 3 – Using your 30m tape, measure the distance between of the string you have just placed. Write down this number.

Step 4 – You now need to calculate the fall (drop) of your gradient over that length. You should know the fall ratio of your pipe, this could be 1:40 , 1:100 etc. You can now use the calculator above “How to Calculate Pipe Rise / Fall”. Here you can plug in your distance between your stakes and the ratio of the pipe. This calculator will then give you the vertical distance down / up.

Step 5 – Now, using your the fall distance you previously calculated, you will bring down the string line on one of the pegs. You will need a tape measure to measure down from the mark that you made on the peg in the previous step. Following this you should now have a string line set to the correct fall gradient.

Step 6 – You can now use your tape measure or spirt level to set out the gradient from this line. You might decide that your pipe needs to be 1 m down from this line. If so, make sure you are measuring down from the line by 1 metre at every location!

Current British Standard guidelines for drainage and sewer systems can be found here. Please check this standard prior to placing drainage schemes to ensure you are compliant.

In the United Kingdom, the Building Regulations 2010 state that wheelchair ramps should have a gradient of no more than 1:12, which means that for every 1 meter of horizontal distance, the ramp should rise no more than 12 centimeters. This gradient is considered to be the maximum gradient that a wheelchair user can safely navigate.

There are some exceptions to this rule. For example, ramps that are used as a secondary means of access (such as an emergency exit) may have a steeper gradient of up to 1:10. In addition, ramps that are used for very short distances (less than 1 meter) may have a gradient of up to 1:8.

It is important to note that the gradient of a ramp is just one factor to consider when designing a ramp for wheelchair users. Other factors that should be taken into account include the width of the ramp, the presence of handrails, and the surface material of the ramp.

Overall, the goal of designing a wheelchair ramp is to create a safe and accessible route for wheelchair users to navigate, and following the guidelines for gradient is an important part of achieving this goal.

92 Bellhouse Lane, Leigh-on-Sea, Southend-On-Sea, Essex, SS9 4PQ

76 Quill Street, Finsbury Park, London, N4 2AD

THS Concepts has a passionate team of surveyors and CAD draughtsman delivering detailed, thorough and accurate surveys and CAD drawings. We are far more than just a land and building surveying company.

Terms & Conditions | XML Sitemap | Copyright 2022 – THS Concepts LTD